Scorpion Motors

Scorpion motors became a major selling brand, great quality , decent price and performance is unmatched

Motor Scorpion HKII 4525-520 ULTIMATE 55mm shaft, Mikado logo 700 special

| Through improvements in motor design and materials, we have been able to increase the efficiency and power conversion of this motor with an entirely new EM field design, while improving the compatibility with various speed controllers available on the market. This new design motor will deliver even more power to your helicopter, with increased efficiency! With the new HKII-4525-520kv Ultimate motor, we have once again raised the bar and created a new benchmark for 700-class helicopter power! Each of the new HKII-4525-520KV ULTIMATE motor is wound with a single strand of 1.4mm wire for the highest possible efficiency. This motor is capable of running continuously at an input power of 4450 watts at 100 amps, and can handle peak inputs of 10200 watts and 230 amps for 2 seconds Scorpion Competition Series Brushless Motors are built from the best materials available, and are designed to provide both quality and performance at an affordable price. Scorpion starts with high quality aluminum alloy parts that are produced on the latest CNC milling machines. These parts are then gold Electro-Coated to provide a beautiful, long-lasting finish. The stators are made with 0.2mm lamination to give maximum efficiency, and minimum Eddy current losses. The stators are epoxy coated to prevent shorts, and are wound with wire that is rated at 180 degrees C (356 F). The magnets used in Scorpion Motors are custom manufactured to be able to withstand high temperatures, making a motor that is virtually impossible to burn up in

|

€330.00

€272.73 Ex VAT

Motor Scorpion Limited Edition HK-4535 380kv ULTIMATE 55mm shaft, Mikado logo 800 special

| Through improvements in motor design and materials, we have been able to increase the efficiency and power conversion of this motor with an entirely new EM field design, while improving the compatibility with various speed controllers available on the market. This new design motor will deliver even more power to your helicopter, with increased efficiency! |

€529.00

€437.19 Ex VAT

Scorpion 450 Class Electric Heli HK-2520-1880KV Brushless Motor (3.5mm shaft)

| Scorpion HK-2520-1880KV Brushless Motor (3.5mm shaft) is specially made for a use on 450 class electric helicopters running on 6-cell Li-Po power such as WARP 360. This motor is designed to provide all the power that you can use, while still maintaining excellent efficiency and cool running characteristics. The 3.5mm shaft kit which is specialize for the new generation 450 class electric helicopter.

Included in the Box:

|

€99.00

€81.82 Ex VAT

Scorpion 450 Class Electric Heli HK-2520-3500KV Brushless Motor (3.5mm shaft)

| Scorpion HK-2520-3500KV Brushless Motor (3.5mm shaft) is specially designed for 450 class electric helicopters running on 4-cell Li-Po power such as WARP 360. This motor is designed to provide all the power that you can use, while still maintaining excellent efficiency and cool running characteristics. The 3.5mm shaft kit which is specialize for the new generation 450 class electric helicopter.

Included in the Box:

|

€99.00

€81.82 Ex VAT

Scorpion 500 Class Electric Heli HK5-4015-805kv brushless motor

| We introduce the fifth generation of Scorpion's renowned and award winning "HK - Series" motors. The Scorpion "HK5 - Series" The HK5 Series lives up to and exceeds our standards of the most Powerful and Efficient motors, with market leading Torque per Amp capabilities. In addition, on the HK5 series we focused specifically on motor cooling and motor temperature. With an all new Internal Fan design, combined with our proven external centrifugal fan, we have nearly doubled the amount of airflow passing through the motor. The result is much improved cooling, and cooler operating temperatures. The HK5-4015-805kv is designed primarily as a lower power option for the SAB RAW 500 helicopter based on the guidelines set forth by SAB Factory directly. Specifications Motor Kv 805KV RPM/Volt |

€189.00

€156.20 Ex VAT

Scorpion 500 Class Electric Heli HK-3226-1400KV Brushless Motor

| Scorpion HK-3226 motors have been developed for the 500 class electric helicopters (425-450mm blade). These motors are designed to provide all the power that you can use, while still maintaining excellent efficiency and cool running characteristics.

Included in the Box:

|

€143.00

€118.18 Ex VAT

Scorpion 500 Class Electric Heli HK-3226-1600KV Brushless Motor

| Scorpion HK-3226 motors have been developed for the 500 class electric helicopters (425-450mm blade). These motors are designed to provide all the power that you can use, while still maintaining excellent efficiency and cool running characteristics. Scorpion HK Series Brushless Motors are built from the best materials available, and are designed to provide both quality and performance at an affordable price. Scorpion starts with high quality aluminum alloy parts that are produced on the latest CNC milling machines. These parts are then gold anodized to provide a beautiful, long-lasting finish. The stators are made with 0.2mm laminations to give maximum efficiency, and minimum Eddy current losses. The stators are epoxy coated to prevent shorts. Unlike other motor manufactures that use off-the-shelf NdFeB magnets with a maximum Curie temperature of 80 to 100 degrees C, our motor magnets are custom manufactured to be able to withstand high temperatures. The wire we use to wind the stators is rated to 180 degrees C (356 F), so it can take the heat and keep on performing. All Scorpion HK-3226 series motors come with 4mm male Bullet style connectors already attached, and include a hardware package that contains 3 matching female Bullet connectors for your speed controller with matching heat shrink tubing. Since the HK series motors are primarily designed for Helicopter and Ducted Fan use, they do not include a prop adapter. If you intend on running a prop on this motor, you will need to purchase a prop adapter for a 5mm shaft. Scorpion Motors are built to last, and are backed with a 2-Year warranty against defects in materials or workmanship. However, due to the high RPM of these motors, and the fact that we cannot control the installation and setup, the bearings are not covered by the 2-Year warranty, nor is any subsequent damage caused to the motor by a bearing failure. Bearings are a normal wear item, and as such, need to be maintained and changed periodically. For maximum life, make sure that a sufficient gap is left between the pinion and main gear during motor installation to avoid binding, and put a small drop of oil on each bearing every 5-6 flights. It is the responsibility of the pilot to ensure that the bearings are maintained properly. Specifications:

Stator Thickness 26.0 mm (1.02 in) No. of Stator Arms 9 Magnet Poles 6 Motor Wind 7 Turn Delta Motor Wire 26-Strand 0.23mm Motor Kv 1600Kv RPM/Volt No-Load Current(Io/10V) 2.19 Amps Motor Resistance (Rm) 0.011 Ohms Max Continuous Current 70 Amps Max Continuous Power 1550 Watts Weight 239 Grams (7.77 oz) Outside Diameter 40.9 mm (1.61 in) Shaft Diameter 4.98 mm (0.19 in) Body Length 50.5 mm (1.99 in) Overall Shaft Length 75.5 mm (2.97 in) Max Lipo Cell 6s Max Peak Current 90A (2 seconds) Max Peak Power 2000 Watts (2 seconds) Motor Timing 5deg Drive Frequency 8kHz Included in the Box:

|

€143.00

€118.18 Ex VAT

Scorpion 500 Class Electric Heli HK-4015-1450KV Brushless Motor

| The Scorpion HK-4015-1450KV motors have been developed for the 500 class electric helicopters with 425 to 450mm blade for 6s Lipo setup. These motors are designed to provide all the power that you can use, while still maintaining excellent efficiency and cool running characteristics. Scorpion HK Series Brushless Motors are built from the best materials available, and are designed to provide both quality and performance at an affordable price. Scorpion starts with high quality aluminum alloy parts that are produced on the latest CNC milling machines. These parts are then gold anodized to provide a beautiful, long-lasting finish. The stators are made with 0.2mm laminations to give maximum efficiency, and minimum Eddy current losses. The stators are epoxy coated to prevent shorts, and are wound with wire that is rated at 180 degrees C (356 F). The magnets used in Scorpion Motors are rated for operation at 200 degrees C (392 F), making a motor that is virtually impossible to burn up in normal use. All Scorpion HK-4015 series motors come with 4mm male Bullet style connectors already attached, and include a hardware package that contains 3 matching female Bullet connectors for your speed controller with matching heat shrink tubing. For maximum strength, the Scorpion HK-4015 series motors feature an 6mm motor shaft that is ground down to a 5mm diameter at the output end to fit standard size pinion gears. Since the HK series motors are primarily designed for Helicopter and Ducted Fan use, they do not include a prop adapter. If you intend on running a prop on this motor, you will need to purchase a prop adapter for a 5mm shaft. Scorpion Motors are built to last, and are backed with a 2-Year warranty against defects in materials or workmanship. However, due to the high RPM of these motors, and the fact that we cannot control the installation and setup, the bearings are not covered by the 2-Year warranty, nor is any subsequent damage caused to the motor by a bearing failure. Bearings are a normal wear item, and as such, need to be maintained and changed periodically. For maximum life, make sure that a sufficient gap is left between the pinion and main gear during motor installation to avoid binding, and put a small drop of oil on each bearing every 5-6 flights. It is the responsibility of the pilot to ensure that the bearings are maintained properly. For the best overall combination of quality, performance, and value, use Scorpion Motors in your helicopter! Specifications:

Included in the Box:

|

€129.00

€106.61 Ex VAT

Scorpion 500 Class Electric Heli HK3226-1900KV Brushless Motor

| Description: Scorpion HK-3226 motors have been developed for the 500 class electric helicopters (425-450mm blade). These motors are designed to provide all the power that you can use, while still maintaining excellent efficiency and cool running characteristics. Scorpion HK Series Brushless Motors are built from the best materials available, and are designed to provide both quality and performance at an affordable price. Scorpion starts with high quality aluminum alloy parts that are produced on the latest CNC milling machines. These parts are then gold anodized to provide a beautiful, long-lasting finish. The stators are made with 0.2mm laminations to give maximum efficiency, and minimum Eddy current losses. The stators are epoxy coated to prevent shorts. Unlike other motor manufactures that use off-the-shelf NdFeB magnets with a maximum Curie temperature of 80 to 100 degrees C, our motor magnets are custom manufactured to be able to withstand high temperatures. The wire we use to wind the stators is rated to 180 degrees C (356 F), so it can take the heat and keep on performing. All Scorpion HK-3226 series motors come with 4mm male Bullet style connectors already attached, and include a hardware package that contains 3 matching female Bullet connectors for your speed controller with matching heat shrink tubing. Since the HK series motors are primarily designed for Helicopter and Ducted Fan use, they do not include a prop adapter. If you intend on running a prop on this motor, you will need to purchase a prop adapter for a 5mm shaft. Specifications:

|

€143.00

€118.18 Ex VAT

Scorpion 500 class HK5-3220-955KV Brushless Motor

| We introduce the fifth generation of Scorpion's renowned and award winning "HK - Series" motors. The Scorpion "HK5 - Series" The HK5 Series lives up to and exceeds our standards of the most Powerful and Efficient motors, with market leading Torque per Amp capabilities. In addition, on the HK5 series we focused specifically on motor cooling and motor temperature. With an all new Internal Fan design, combined with our proven external centrifugal fan, we have nearly doubled the amount of airflow passing through the motor. The result is much improved cooling, and cooler operating temperatures. The HK5-3220-955kv is designed primarily for the SAB RAW 420C helicopter based on the guidelines set forth by SAB Factory directly. Specifications Motor Kv 955KV RPM/Volt |

€179.99

€148.75 Ex VAT

Scorpion 500 class HK5-4020-850kv Brushless Motor #HK5-4020-850

| We introduce the fifth generation of Scorpion's renowned and award winning "HK - Series" motors. The Scorpion "HK5 - Series" The HK5 Series lives up to and exceeds our standards of the most Powerful and Efficient motors, with market leading Torque per Amp capabilities. In addition, on the HK5 series we focused specifically on motor cooling and motor temperature. With an all new Internal Fan design, combined with our proven external centrifugal fan, we have nearly doubled the amount of airflow passing through the motor. The result is much improved cooling, and cooler operating temperatures. The HK5-4020-850kv is designed primarily for the SAB RAW 500 helicopter based on the guidelines set forth by SAB Factory directly. |

€209.00

€172.73 Ex VAT

Scorpion 550 Class Heli HKIV- 4020-1060KV Brushless Motor

| From 2010 when Scorpion HKIII-40 series is released, a lot of feedback by World Champions and pilots in all facets of the hobby are received that they have well established themselves as the Gold Standard of R/C model power! The HKIII-4020 series motors have proven themselves to be extremely successful in heli community, and has become the most popular motor used in 400~500 class helicopters world-wide. And now we are pleased to announce the release of the forth generation HKIV-4020 series motors. With the same motor design and materials of HKII-45 series, and single strand winding technique on this size of motor, it has the better efficiency and power conversion than HKIII-40 series, with an entirely new EM field design, while improving the compatibility with various speed controllers available on the market. This new design motor will deliver even more power to your helicopter, with increased efficiency! Specifications Stator Thickness 20 mm(0.79 in) No. of Stator Arms 12 Magnet Poles 10 Motor Wind 4+4 Turn Delta Motor Wire 1-Strand 1.6mm Motor Kv 1060KV RPM/Volt No-Load Current (IO/10v) 4.03 Amps Motor Resistance (RM) 0.009 Ohms Max Continuous Current 78 Amps Max Continuous Power 1731 Watts Weight 310 Grams (10.94 oz) Outside Diameter 49.50 mm (1.95 in) Shaft Diameter 4.98 mm (0.20 in) Body Length 49.2 mm (1.94 in) Overall Shaft Length 80 mm (3.15 in) Max Lipo Cell 6s Peak Continuous Current 90 Amps (5 seconds) Peak Continuous Power 1998 Watts (5 seconds) Motor Timing 5deg Drive Frequency 8kHz |

€224.00

€185.12 Ex VAT

Scorpion 5G HK5-5024-475KV series 700 class brushless motor #HK5-5024-475kv 14s

| The Scorpion "HK5 - Series" : the fifth generation of Scorpion's renowned and award winning MOTOR, 2 SHAFT LENGTHS possible, 6x55mm and 6x36mm The HK5 Series lives up to and exceeds our standards of the most Powerful and Efficient motors, with market leading Torque per Amp capabilities. In addition, on the HK5 series we focused specifically on motor cooling and motor temperature. With an all new Internal Fan design, combined with our proven external centrifugal fan, we have nearly doubled the amount of airflow passing through the motor. The result is much improved cooling, and cooler operating temperatures. The HK5-5024-475kv is designed primarily for High Power 700 class helicopters. With the larger Stator Diameter, it provides more torque and more power, for equal weight as compared to the previous HKII-4530-540kv motor. specifications |

€399.00

€329.75 Ex VAT

Scorpion 5G HK5-5024-535KV series 700 class brushless motor #HK5-5024-535kv

| The Scorpion "HK5 - Series" : the fifth generation of Scorpion's renowned and award winning MOTOR, 2 SHAFT LENGTHS possible, 6x55mm and 6x36mm The HK5 Series lives up to and exceeds our standards of the most Powerful and Efficient motors, with market leading Torque per Amp capabilities. In addition, on the HK5 series we focused specifically on motor cooling and motor temperature. With an all new Internal Fan design, combined with our proven external centrifugal fan, we have nearly doubled the amount of airflow passing through the motor. The result is much improved cooling, and cooler operating temperatures. The HK5-5024-535kv is designed primarily for High Power 700 class helicopters. With the larger Stator Diameter, it provides more torque and more power, for equal weight as compared to the previous HKII-4530-540kv motor. specifications |

€399.00

€329.75 Ex VAT

Scorpion 600 Class Electric Heli Brushless Motor HK-3536-510Kv

| Scorpion HK-3536 motors have been developed for the 600 class electric helicopters with narrow motor frame such as Trex-600. These motors are designed to provide all the power that you can use, while still maintaining excellent efficiency and cool running characteristics.

Included in the Box:

|

€199.00

€164.46 Ex VAT

Scorpion 600 Class Heli HK5-4026-1115kv Motor 5mm shaft-Mikado version

| We introduce the fifth generation of Scorpion's renowned and award winning "HK - Series" motors. The Scorpion "HK5 - Series" The HK5 Series lives up to and exceeds our standards of the most Powerful and Efficient motors, with market leading Torque per Amp capabilities. In addition, on the HK5 series we focused specifically on motor cooling and motor temperature. With an all new Internal Fan design, combined with our proven external centrifugal fan, we have nearly doubled the amount of airflow passing through the motor. The result is much improved cooling, and cooler operating temperatures. Specifications , this motor used on Mikado helis mostly Motor Kv 1115KV RPM/Volt |

€259.90

€214.79 Ex VAT

Scorpion 600 Class Heli HK5-4026-1115kv Motor 6mm shaft

| We introduce the fifth generation of Scorpion's renowned and award winning "HK - Series" motors. The Scorpion "HK5 - Series" The HK5 Series lives up to and exceeds our standards of the most Powerful and Efficient motors, with market leading Torque per Amp capabilities. In addition, on the HK5 series we focused specifically on motor cooling and motor temperature. With an all new Internal Fan design, combined with our proven external centrifugal fan, we have nearly doubled the amount of airflow passing through the motor. The result is much improved cooling, and cooler operating temperatures. Specifications Motor Kv 1115KV RPM/Volt |

€259.90

€214.79 Ex VAT

Scorpion 600 Class Heli HK5-4026-815kv Motor 6mm shaft 32mm long

| We introduce the fifth generation of Scorpion's renowned and award winning "HK - Series" motors. The Scorpion "HK5 - Series" The HK5 Series lives up to and exceeds our standards of the most Powerful and Efficient motors, with market leading Torque per Amp capabilities. In addition, on the HK5 series we focused specifically on motor cooling and motor temperature. With an all new Internal Fan design, combined with our proven external centrifugal fan, we have nearly doubled the amount of airflow passing through the motor. The result is much improved cooling, and cooler operating temperatures. Specifications Motor Kv 815KV RPM/Volt |

€259.90

€214.79 Ex VAT

Scorpion 600 Class Heli HKII-4225-500KV Brushless Motor Limited Edition

| Scorpion HKII-4225-500KV Brushless Motor Limited Edition is specially designed for a use on 600 class or light 700 class helicopters running on 12-cell Li-Po power. This motor represents the most technologically advanced power source ever offered for a 600 class electric helicopter. Each of the new HKII-4225 Limited Edition motor is wound with a single strand of 1.3mm wire for the highest possible efficiency. This motor is capable of running continuously at an input power of 3550 watts at 80 amps, and can handle peak inputs of 5770 watts and 130 amps.

Included in the Box:

Note:

|

€329.00

€271.90 Ex VAT

Scorpion 600 Class Heli HKIII-4225-610KV Brushless Motor Limited Edition

| Scorpion HKIII-4225-610KV Brushless Motor Limited Edition is specially designed for a use on 600 class helicopters running on 12-cell Li-Po power. This motor represents the most technologically advanced power source ever offered for a 600 class electric helicopter. Each of the new HKII-4225 Limited Edition motor is wound with a single strand of 1.4mm wire for the highest possible efficiency. This motor is capable of running continuously at an input power of 3550 watts at 80 amps, and can handle peak inputs of 5770 watts and 130 amps.

Note:

|

€329.00

€271.90 Ex VAT

Scorpion 600-700 Class Heli HKII-4225-550KV Brushless Motor Limited Edition

| With the trend of ultra light weight 700 size models on the rise, the market called for a light weight, yet ultra powerful motor. So Scorpion brought back the HKII-4225-550kv for a Limited Edition run! Sized directly between our proven HKIV-4025 and HKII-4525 motors in terms of weight and power, and LIGHTER yet MORE powerful then our competitors 4030 motors, this motor represents the most technologically advanced power source ever offered for an electric helicopter. Each of the new HKII-4225 Limited Edition motor is hand wound with a single strand of 1.35mm wire for the highest possible efficiency. This motor is capable of running continuously at an input power of 3550 watts at 80 amps, and can handle peak inputs of 5770 watts and 130 amps. Perfect for a Light weight 700 size, or monster 600 size power system on 12s. Scorpion Competition Series Brushless Motors are built from the best materials available, and are designed to provide both quality and performance at an affordable price. Scorpion starts with high quality aluminum alloy parts that are produced on the latest CNC milling machines. These parts are then gold Electro-Plated to provide a beautiful, long-lasting finish. The stators are made with 0.2mm laminations to give maximum efficiency, and minimum Eddy current losses. The stators are epoxy coated to prevent shorts, and are wound with wire that is rated at 180 degrees C (356 F). The magnets used in Scorpion Motors are rated for operation at 200 degrees C (392 F), making a motor that is virtually impossible to burn up in normal use. Scorpion Motors are built to last, and are backed with a 1-Year warranty against defects in materials or workmanship. However, due to the high RPM of these motors, and the fact that we cannot control the installation and setup, the bearings are not covered by the 1-Year warranty, nor is any subsequent damage caused to the motor by a bearing failure. Bearings are a normal wear item, and as such, need to be maintained and changed periodically. For maximum life, make sure that a sufficient gap is left between the pinion and main gear during motor installation to avoid binding, and put a small drop of oil on each bearing every 5-6 flights. It is the responsibility of the pilot to ensure that the bearings are maintained properly. For the best overall combination of quality, performance, and value, use Scorpion Motors in your helicopter

|

€299.00

€247.11 Ex VAT

Scorpion 700 Class Electric Heli HKIII-5020-450KV Brushless Motor

| Scorpion HKIII-5020-450KV Brushless Motor is designed for 700 class Electric Helicopters, and for people that want to convert their 90 size glow helicopter to electric power. This motor has a maximum continuous power rating of 3770 watts at 85 amps, and a peak power rating of 5320 watts at 120 amps! The larger diameter 50mm stator allows these motors to produce insane amounts of torque.

|

€359.00

€296.69 Ex VAT

Scorpion 700 Class Electric Heli HKIII-5020-520KV Brushless Motor

| Scorpion HKIII-5020-520KV Brushless Motor is designed for 700 class Electric Helicopters, and for people that want to convert their .90 size glow helicopter to electric power. This motor has a maximum continuous power rating of 3770 watts at 85 amps, and a peak power rating of 5320 watts at 120 amps! The larger diameter 50mm stator allows these motors to produce insane amounts of torque. Specifications:

|

€359.00

€296.69 Ex VAT

Scorpion 700 Class Heli Brushless Motor HKIV-4035-520kv

| With the same motor design and materials of HKII-45 series, and single strand winding technique on this size of motor, it has the better efficiency and power conversion than HKIII-40 series, with an entirely new EM field design, while improving the compatibility with various speed controllers available on the market. This new design motor will deliver even more power to your helicopter, with increased efficiency!

1 x Scorpion HKIV-4035-500KV Motor 3 x Female Connectors 3 x Connector Cover 4 x M4 Screws |

€319.00

€263.64 Ex VAT

Scorpion 700 Class Heli HK-4530-500KV 6mm XL shaft Brushless Motor Limited Edition

| Scorpion HK-4530-500KV 6mm shaft Brushless Motor Limited Edition is specially designed for a use on 700 class helicopters running on 12-cell Li-Po power. This motor represents the most technologically advanced power source ever offered for a 700 class electric helicopter and also produces 20% more torque than the Scorpion popular HKIII-4035 series motors and exceed 89% efficiency.

Included in the Box: 1 x Scorpion HK-4530-500KV 6mm XL Shaft Motor |

€389.00

€321.49 Ex VAT

Scorpion 700 Class Heli HK5-4035-455kv Brushless Motor

| We introduce the fifth generation of Scorpion's renowned and award winning "HK - Series" motors. The Scorpion "HK5 - Series" The HK5 Series lives up to and exceeds our standards of the most Powerful and Efficient motors, with market leading Torque per Amp capabilities. In addition, on the HK5 series we focused specifically on motor cooling and motor temperature. With an all new Internal Fan design, combined with our proven external centrifugal fan, we have nearly doubled the amount of airflow passing through the motor. The result is much improved cooling, and cooler operating temperatures. The HK5-4035-455kv is designed for 600 - lightweight 700 size of helicopter running 12s - 14s lipo, or UAV application requiring up to 8200w of power.

Specifications |

€319.00

€263.64 Ex VAT

Scorpion 700 Class Heli HKII-4530-500KV 6mm 55mm shaft Brushless Motor

| Scorpion HKII-4530-500KV 6mm shaft Brushless Motor is specially designed for a use on 700 class helicopters running on 12-cell Li-Po power. This motor represents the most technologically advanced power source ever offered for a 700 class electric helicopter and also produces 20% more torque than the Scorpion popular HKIII-4035 series motors and exceed 89% efficiency.

Stator Thickness 30 mm (1.18 in) No. of Stator Arms 12 No. of Stator Poles 10 Motor Wind 5T+5T Turn Wye Motor Wire 1-Strand 1.5 mm Motor Kv 500KV RPM/Volt No-Load Current (Io/10V) 2.12 Amps Motor Resistance (RM) 0.012 Ohms Max Continuous Current 115 Amps Max Continuous Power 4800 Watts Weight 598 Grams (21.09 oz) Outside Diameter 56.9 mm (2.24 in) Shaft Diameter 5.98 mm (0.24 in) Body Length 62.3 mm (2.45 in) Overall Shaft Length 117.3 mm (4.62 in) Max Lipo Cell 12s Max Peak Current 250A (2 seconds) Max Peak Power 11000 Watts (2 seconds) Motor Timing 5deg to 15 deg Drive Frequency 8kHz Included in the Box: 1 x Scorpion HK-4530-500KV 6mm XL Shaft Motor |

€469.00

€387.60 Ex VAT

Scorpion 700 Class Heli HKII-4530-540KV Brushless Motor 6mm 55mm

| Scorpion HKII-4530-540KV Brushless Motor Limited Edition is specially designed for a use on 700 class helicopters running on 12-cell Li-Po power. This motor represents the most technologically advanced power source ever offered for a 700 class electric helicopter and also produces 20% more torque than the Scorpion popular HK4035 series motors and exceed 89% efficiency. Specifications Stator Diameter 45 mm (1.77 in)Stator Thickness 30 mm (1.18 in) No. of Stator Arms 12 No. of Stator Poles 10 Motor Wind 5T+4T Turn Wye Motor Wire 1-Strand 1.5 mm Motor Kv 540KV RPM/Volt No-Load Current (Io/10V) 2.54 Amps Motor Resistance (RM) 0.010 Ohms Max Continuous Current 115 Amps Max Continuous Power 4800 Watts Weight 588 Grams (20.74 oz) Outside Diameter 56.9 mm (2.24 in) Shaft Diameter 5.98 mm (0.24 in) Body Length 62.3 mm (2.45 in) Overall Shaft Length 117.3 mm (4.62 in) Max Lipo Cell 12s Max Peak Current 250A (2 seconds) Max Peak Power 11000 Watts (2 seconds) Motor Timing 5deg to 15 deg Drive Frequency 8kHz |

€469.00

€387.60 Ex VAT

Scorpion 700 Class Heli HKIV-4035-560KV Brushless Motor

| From 2010 when Scorpion HKIII-40 series is released, a lot of feedback by World Champions and pilots in all facets of the hobby are received that they have well established themselves as the Gold Standard of R/C model power! The HKIII-4035 series motors have proven themselves to be extremely successful in heli community and has become the most popular motor used in 600 ~ 700 class helicopters world-wide. And now we are pleased to announce the release of the fourth generation HKIV-4035 series motors. With the same motor design and materials of HKII-45 series, and single strand winding technique on this size of motor, it has the better efficiency and power conversion than HKIII-40 series, with an entirely new EM field design, while improving the compatibility with various speed controllers available on the market. This new design motor will deliver even more power to your helicopter, with increased efficiency! Specifications

Included in the Box

|

€319.00

€263.64 Ex VAT

Scorpion 700-800 class HK5-4525-535KV 12s brushless motor

| We introduce the fifth generation of Scorpion's renowned and award winning "HK - Series" motors. The Scorpion "HK5 - Series" The HK5 Series lives up to and exceeds our standards of the most Powerful and Efficient motors, with market leading Torque per Amp capabilities. In addition, on the HK5 series we focused specifically on motor cooling and motor temperature. With an all new Internal Fan design, combined with our proven external centrifugal fan, we have nearly doubled the amount of airflow passing through the motor. The result is much improved cooling, and cooler operating temperatures. The HK5-4525-535kv is designed for 700 size helicopters on 12s lipo, or other UAV application requiring up to 10,200w of power. Specifications

|

€330.00

€272.73 Ex VAT

Scorpion 800 Class Electric Heli HK-5035-500KV Brushless Motor

| The Scorpion HK-5035-500 motor will provide all the power you need for the larger 800 class electric helicopters, those massive electric powered scale projects or for your workhorse camera platform helicopters that need to be able to lift heavy weights reliably.

|

€479.00

€395.87 Ex VAT

Scorpion 800 Class Electric Heli motor HKIII-5035-380KV (8mm 55mm)

| Scorpion HKIII-5035-380KV Brushless Motor will provide all the power you need for the larger 800 class electric helicopters, those massive electric powered scale projects or for your workhorse camera platform helicopters that need to be able to lift heavy weights reliably. Specifications:

Stator Thickness 35 mm (1.38 in) No. of Stator Arms 12 Magnet Poles 10 Motor Wind 5+5 Turn Delta Motor Wire 1-Strand 1.6 mm Motor Kv 380KV RPM / Volt No-Load Current (Io/10V) 2.9 Amps Motor Resistance (Rm) 0.0161 Ohms Max Continuous Current 99 Amps Max Continuous Power 5128 Watts Weight 785 Grams (27.67 oz) Outside Diameter 62.2 mm (2.45 in) Shaft Diameter 7.98 mm (0.31 in) Body Length 69.2 mm (2.73 in) Overall Shaft Length 124.80 mm (4.91 in) Max Lipo Cell 14s Max Peak Current 137 A (5 seconds) Max Peak Power 7097 Watts (5 seconds) Motor Timing 5deg Drive Frequency 8kHz |

€489.00

€404.13 Ex VAT

Scorpion A-4225 V2 PNP Combo (6s/90E+/20cc-25cc+/3108w)

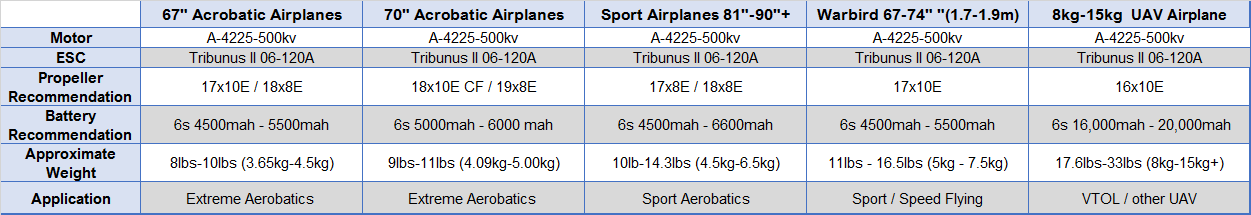

| In combination with our new A-Series motor line debut, we are also please to announce our new "PLUG-N-POWER" combo kits! We wanted to take the guess work out of Electric Power Systems, and provide our customers with a simple, convenient and reliable power system for their 90E /20cc-25cc sized airplanes commonly used in 67"-70" acorbatic airframes . The A-4225 PNP Combo is the solution. This pairs our high power and high efficiency A-series motors with one of our suitably sized, pre-programmed, Tribunus III ESCs! Providing you with a tested, proven, and convenient power system combo, which is sure to provide you immense power, at the best efficiency! This PNP combo is ready to easily bolt on, and give you the power you need, with the efficiency you want. Recommended Propeller : 17x10 / 18x8 Recommended Battery : 6s 4400mah - 5500mah

MOTOR SPECIFICATIONS :

Use Case Applications Included in the Box1 x A-4225-500kv Motor | ||||||||||||||||||||||||||||||||||||||||||||||

€489.00

€404.13 Ex VAT

Scorpion A-5524-205kv V2 Airplane Brushless motor #A_5524_205

| The Scorpion A-Series motors are designed to deliver unparalleled performance and efficiency for freestyle aerobatic and UAV aircraft applications. Featuring a meticulously engineered rotor with optimized magnets, high-grade 0.2mm silicon steel stator sheets, and premium dual-strand 0.96mm enamel-coated copper windings (rated above 200°C), the A-Series motors deliver exceptional power output combined with remarkable reliability and longevity. The A-5524-205kv motor is specifically engineered for aerobatic airplanes ranging from 74" to 78" wingspan, as well as sport and UAV aircraft requiring power levels up to 5000W on a 12S LiPo setup. Recommended Setup :

Motor Specifications :

Note: Always ensure your power system (ESC, battery, and propeller) is correctly sized to match the motor’s specifications and intended use. |

€399.99

€330.57 Ex VAT

Scorpion A-7445-140kv Airplane-UAV Brushless motor replacement of 150-170cc engines

| The Scorpion A - Series line of motors was designed to be the most optimal and premier choice of motor for your freestyle or UAV airplane. We have achieved incredible performance through incredible efficiency. By optimizing the magnets in the rotor, and using the best quality 0.2mm thickness silicon steel stator sheets, and single strand enamel coated copper wire windings rated above 200C+, the performance and efficiency results are unlike anything we have seen before! Combined with a robust design which has been tested extensively by our world class team pilots for longevity and reliability, we feel this motor checks and exceeds all measurable categories! The A-7445 was designed specifically for airplanes requiring a 150cc - 170cc equivalent gas engine, or other airframes requiring up to 10,000w of power. Recommended Prop Selection : For 12s - 30x12C2E - 33x10C2E = 150cc performance For 14s - 28x12C2E - 30x12 C2E = 150cc performance Recommended ESC -: Tribunus II 14-300A ESC SBECNOTE: Due to the large size of airframes in this class, normally the battery wires must be extended. Running to long of battery cables WILL damage ESC and void your warranty. Precautions must be taken. We recommend the use of an additional capacitor bank such as the APD 100V 800uF. Acrobatic Weight Range -: 15.0kg - 25.0kg - kg (33.0lbs - 55.0lbs) Sport / UAV (single engine) Weight Range : - 21.5kg - 64kg (47.4lbs -142.0lbs) Specifications |

€999.00

€825.62 Ex VAT

Scorpion A-7445-165kv Airplane Brushless motor replacement of 150-170cc engines

| The Scorpion A - Series line of motors was designed to be the most optimal and premier choice of motor for your freestyle or UAV airplane. We have achieved incredible performance through incredible efficiency. By optimizing the magnets in the rotor, and using the best quality 0.2mm thickness silicon steel stator sheets, and single strand enamel coated copper wire windings rated above 200C+, the performance and efficiency results are unlike anything we have seen before! Combined with a robust design which has been tested extensively by our world class team pilots for longevity and reliability, we feel this motor checks and exceeds all measurable categories! The A-7445 was designed specifically for airplanes requiring a 150cc - 170cc equivalent gas engine, or other airframes requiring up to 10,000w of power. Recommended Prop Selection :30x12 C2E = Optimal / 150cc performance 32x10 C2E = High Alt Recommended ESC -: Tribunus II 14-300A ESC SBEC NOTE: Due to the large size of airframes in this class, normally the battery wires must be extended. Running to long of battery cables WILL damage ESC and void your warranty. Precautions must be taken. We recommend the use of an additional capacitor bank such as the APD 100V 800uF. Acrobatic Weight Range -: 15.0kg - 25.0kg - kg (33.0lbs - 55.0lbs) Sport / UAV (single engine) Weight Range : - 21.5kg - 64kg (47.4lbs -142.0lbs) Specifications |

€999.00

€825.62 Ex VAT